In the fast-paced world of aquaculture, particularly in shrimp farming, the demand for top-tier feed production equipment is more critical than ever. Shrimp feed pellet machines are at the forefront of this technological evolution, with manufacturers pushing the limits of what these machines can achieve. This article delves into the highest configuration of shrimp feed pellet machines available today, highlighting their advanced features, performance capabilities, and the benefits they offer to shrimp feed manufacturers.

Cutting-Edge Technological Features

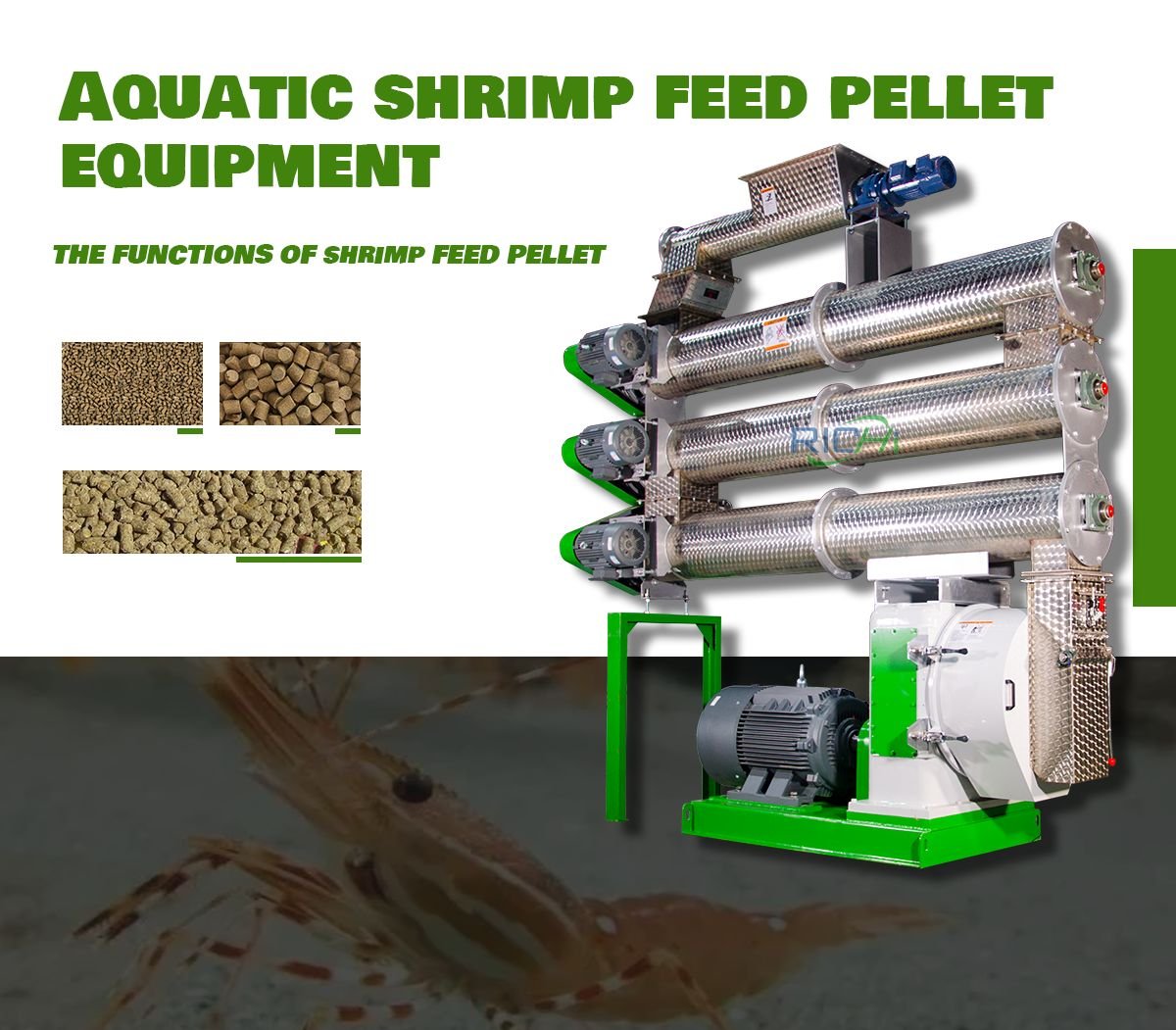

The most advanced shrimp feed pellet machines are equipped with state-of-the-art technology designed to optimize efficiency, enhance pellet quality, and maximize production output. Key features of these top-tier machines include:

- High-Capacity Output: These machines can produce between 20 to 25 tons of high-quality shrimp feed pellets per hour. This impressive output is made possible by advanced die and roller designs, powerful motors, and efficient material flow systems.

- Multi-Layer Conditioning: High-end models are equipped with three or four-layer conditioning systems, ensuring thorough moisture distribution, optimal starch gelatinization, and protein denaturation. This results in superior pellet quality with enhanced water stability.

- Precision Control Systems: Featuring sophisticated PLC (Programmable Logic Controller) systems with touchscreen interfaces, these machines allow for precise, real-time control over every aspect of the pelletizing process, ensuring consistent pellet quality.

- Variable Frequency Drives (VFDs): Integrated VFDs for the main motor, feeder, and conditioner provide fine-tuning capabilities, allowing the machine to adapt to different feed formulations and desired pellet characteristics.

- Advanced Die and Roller Technology: The dies and rollers are crafted from premium, wear-resistant materials, designed to handle high-moisture formulations (up to 17-18%) while maintaining excellent pellet durability.

- Automatic Lubrication Systems: These systems ensure the longevity of critical components like bearings and gears, reducing maintenance downtime.

- Energy-Efficient Design: High-efficiency motors, optimized gear transmissions, and heat recovery systems contribute to a more energy-efficient operation, reducing overall energy consumption.

- Integrated Cooling and Drying Systems: Some of the most advanced configurations include built-in cooling and drying systems that work in tandem with the pellet mill, ensuring pellets are produced at the ideal moisture content and temperature for storage and transport.

- Enhanced Hygiene Features: These machines are designed with food-grade stainless steel components and easy-to-clean surfaces, ensuring the highest standards of feed hygiene.

- IoT and Data Analytics Integration: With Internet of Things (IoT) capabilities, these machines allow for remote monitoring, predictive maintenance, and data-driven process optimization.

Superior Performance Capabilities

The highest configuration shrimp feed pellet machines offer exceptional performance across various metrics:

- Pellet Size Versatility: Capable of producing pellets ranging from 0.8mm to 3mm in diameter, these machines can cater to the needs of shrimp at different growth stages.

- Water Stability: The advanced conditioning and pelleting processes result in pellets that maintain integrity in water for 4-6 hours or longer, essential for slow-feeding shrimp.

- Pellet Durability Index (PDI): These machines consistently achieve a PDI of 98% or higher, ensuring minimal fines and waste during handling and feeding.

- Ingredient Processing Flexibility: High-end machines can handle a wide variety of ingredients, including high-fat formulations and alternative protein sources, without compromising on pellet quality.

- Consistent Output: Thanks to precise control systems, these machines maintain consistent pellet quality and production rates, even when dealing with varying ingredient qualities or environmental conditions.

Benefits for Shrimp Feed Manufacturers

Investing in the highest configuration shrimp feed pellet machines brings numerous advantages for manufacturers:

- Enhanced Productivity: The high production capacity of these machines enables manufacturers to meet increasing market demands and expand their operations efficiently.

- Improved Feed Quality: The superior conditioning and pelleting processes result in highly digestible, water-stable pellets that can boost shrimp growth rates and feed conversion ratios.

- Operational Flexibility: The ability to process a diverse range of ingredients and produce various pellet sizes allows manufacturers to adapt quickly to market changes and ingredient availability.

- Cost Efficiency: Energy-efficient designs and reduced maintenance needs translate into significant cost savings over time.

- Consistent Quality: Precision control systems ensure a consistent product, which is essential for maintaining customer satisfaction and brand reputation.

- Enhanced Hygiene and Safety: Advanced hygiene features and automated systems help minimize contamination risks and improve worker safety.

- Data-Driven Optimization: IoT integration and data analytics capabilities enable manufacturers to continuously optimize their production processes and make informed, real-time decisions.

Key Considerations for Implementation

Despite the many advantages, several factors should be considered before investing in these advanced machines:

- Initial Investment: The cost of these machines is substantial, requiring careful consideration of projected returns and market conditions.

- Technical Expertise: Operating and maintaining these sophisticated machines requires skilled personnel, which may necessitate additional training or hiring.

- Infrastructure Needs: High-capacity machines may require facility upgrades, including power supply, steam generation, and material handling systems.

- System Integration: Compatibility with existing production lines and quality control systems is crucial for seamless implementation.

Conclusion

The highest configuration shrimp feed pellet machines represent the cutting edge of feed production technology, offering unmatched performance, efficiency, and quality. These machines are equipped with advanced features such as multi-layer conditioning, precision control, and IoT integration, making them ideal for producing premium shrimp feed pellets.

For shrimp feed manufacturers aiming to remain competitive in a demanding market, investing in these high-end machines can provide a significant advantage. The ability to produce consistently high-quality, water-stable pellets can lead to better shrimp growth, increased customer satisfaction, and higher profitability. (Related post: fish pellet machine price)

However, the decision to adopt such advanced technology should be made with careful consideration of the initial investment, technical requirements, and market needs. As the aquaculture industry continues to evolve, staying at the forefront of feed production technology will be key to long-term success in the competitive shrimp feed market.