Complete Olive Pomace Pellet Production Line Solution

We set up the Complete Olive Pomace Pellet Production Line Solution that will produce pellets with the world standard technologies!

Raw Material

-

Pre-treatment

Section -

Crushing

Section -

Conveying

Section -

Drying

Section -

Pellet Mill

-

Cooling

Section -

Packaging

Section -

Dust Control

System

Finished Product

Pre-treatment : This section is more suitable for the larger raw materials in the early stage, and it is not easy to directly crush or granulate through the crusher. But sometimes this section can be omitted. For example, the sawdust pellet production line can directly pelletize, and this section is not needed.

Crushing Section : This section is usually used in biomass pellet production line, forage gress pellet production line and nutshell straw pellet production line. For example, the SFSP hammer mill is used for wood and fruit shells, and the straw/alfalfa/husk/grass crusher is used for grass and straw. Different raw materials are equipped with different types of crusher.

Conveying Section : Conveying equipment is mechanical equipment that transports bulk cargo and unit goods from a loading point to an unloading point along a certain route in a continuous manner. The conveying equipment of RICHI machinery includes screw conveyor, scraper conveyor, belt conveyor and Bucket elevator.

Drying Section : To dry materials and remove the moisture from 50% to 15-17%. Itincludes: –Burningstove,tosupplyhotair –Drumdryer –Dischargingcyclone.

Pellet Mill: Wood pellet machine, also known as biomass pellet machine, has a wide range of raw materials: straw shells include wood, straw, sawdust, cotton stalks, rice husks, peanut shells, sunflower shells, coconut shells, coffee shells, bamboo, etc. . The grasses are alfalfa, hops, hemp, hay, grass, etc. In addition, there are organic fertilizer granulator, cat litter granulator and so on.

Cooling & Section : Pellets come out from pellet machine, its temperature is around 70℃, by cooling system, It can cool down to room temperature immediately. By momentary cooling, the hardness of pellets will become more stronger.

Screening Section : The forming rate of pellet machine is around 98 % , so there are still have 2% powder in pellets,by screening, sort out all the powders from pellets.

Packaging Section : There are three kinds of automatic packaging machines produced by RICHI machinery: powder packaging machines, granule packaging machines and (universal) dual-purpose packaging machines.

Dust Control System : A dust collection system is an air quality improvement system used in industrial production to improve breathable air quality and safety by removing particulate matter from the air and environment. Dust collection systems work on the basic formula of capture, convey and collect.

Production Line Description

Olive Pomace Introduction

Olive pomace is a valuable by-product extracted from olive oil, it is a thick sludge, the main residue of the olive oil extraction process. It is the remaining pulpy material after removing most of the oil from the olive paste and it consists of pieces of skin, pulp, stone, and olive kernel. On the basis of total olive weight, the pulp makes up about 70–90%, the stone about 9–27%, and the seed about 2–3%.

Depending on the production line (two-phase or three-phase decanter) the pomace may contain more or less water. Two-phase pomace has a moisture percentage close to 70% and contains a certain amount of sugars as a result of the presence of vegetation water, whereas the moisture in pomace from a three-phase system is about 45%. Besides water, olive pomace contains carbohydrates, lipids (remaining oil), phenols, and a number of inorganic compounds, and it has an average pH of 4.8–5.2.

Olive Pomace Distribution

Olive pomace is sourced basically from the areas with large olive tree plantation and a well-established olive oil industry. Olive is the most widely cultivated fruit crops in the world with a cultivation area of more than 10 million ha worldwide, and 95% of world’s olives are produced in the Mediterranean region. Most countries along the Mediterranean Sea produce olive oil in varying quantities. Spain, Italy, and Greece represent more than three-fourths of the total olive oil output in the world.

Since 2014, Spain Olives Production rose 15% year on year. In 2019, the country was ranked number 1 among other countries in Olives Production with 9,176,929 Metric Tons. Italy, Turkey and Greece respectively ranked number 2, 3 and 4 in this ranking. Slovenia witnessed the best average annual growth at +33.6% per year, while Iraq was the worst growing country at -18.2% per year.

Top 10 Countries for Olive Production in 2019

| Top 10 Countries | Metric Tons | Last | YoY | 5 years CAGR | |

| 01 | Spain | 9,176,929.00 | 2019 | -6.5 % | +15.0 % |

| 02 | Italy | 1,945,324.00 | 2019 | +3.6 % | -0.2 % |

| 03 | Turkey | 1,674,377.00 | 2019 | +11.6 % | -1.1 % |

| 04 | Greece | 1,525,543.00 | 2019 | +41.4 % | -10.1 % |

| 05 | Morocco | 1,479,853.00 | 2019 | -5.2 % | -1.2 % |

| 06 | Egypt | 892,753.00 | 2019 | +16.2 % | +9.6 % |

| 07 | Algeria | 854,377.00 | 2019 | -0.7 % | +12.1 % |

| 08 | Portugal | 791,410.00 | 2019 | +6.9 % | +11.7 % |

| 09 | Tunisia | 744,757.00 | 2019 | -9.8 % | +14.7 % |

| 10 | Syria | 358,666.00 | 2019 | -10.3 % | -1.8 % |

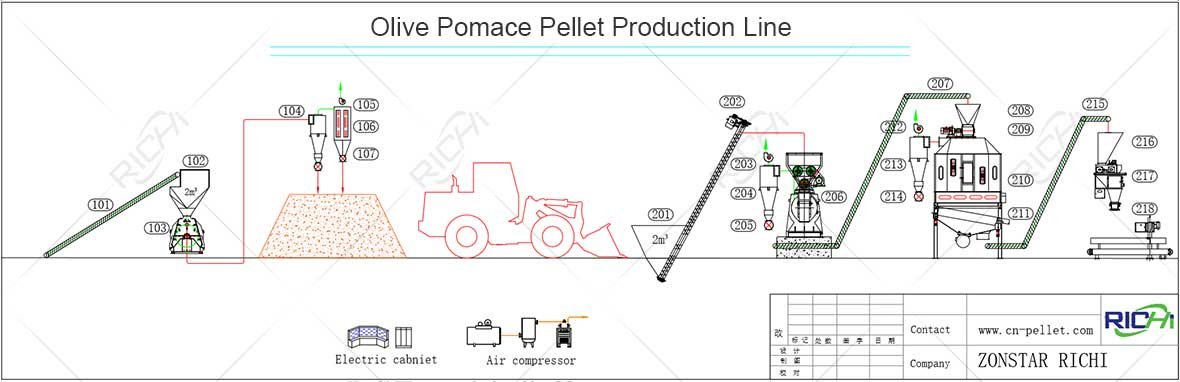

Production Process of Olive Pomace Pellet Production Line

Olive Pomace Pellet Production Line Fowchart

Step 1: Grinding

Olive cake is crushed with the help of hammer mills or a grinder to reduce the size of the olive cake and finally produce a fine powder.

Step 2: Drying

Olive pomace has a high moisture content of 40-70%, depending on the olive oil extraction process. Then a rotary drum dryer is essential. The rotary dryer has a slight inclination, acting as a conveying device and stirrer. The goal of the drying process is to reduce the moisture of olive pomace to approximately 12%, which is suitable for pelletizing.

Step 3: Pelleting

After drying, the olive pomace can be pelletized directly without any further treatment. The ring die olive pomace pellet machine is more proper for olive pomace pellet production. And the ring die compression ratio should be higher than 1:6.5. No adhesive added in this procedure.

Step 4: Cooling

Pomace pellets discharged from pellet mill are high in temperature and moisture content. Our counter current pellet cooler is used to remove pellet heat as well as the moisture content to ensure pellets quality and shelf-life.

Step 5: Sieving

The powder materials or unshaped pomace pellets are sieved and send to the pellet mill again.

Step 6: Packaging

These pellets and briquettes are then packed into different capacity bags for distribution.