Complete Sunflower Seed Shell Pellet Mill Production Line Solution

We set up the Complete Sunflower Seed Shell Pellet Mill Production Line Solution that will produce pellets with the world standard technologies!

Raw Material

-

Pre-treatment

Section -

Crushing

Section -

Conveying

Section -

Drying

Section -

Pellet Mill

-

Cooling

Section -

Packaging

Section -

Dust Control

System

Finished Product

Pre-treatment : This section is more suitable for the larger raw materials in the early stage, and it is not easy to directly crush or granulate through the crusher. But sometimes this section can be omitted. For example, the sawdust pellet production line can directly pelletize, and this section is not needed.

Crushing Section : This section is usually used in biomass pellet production line, forage gress pellet production line and nutshell straw pellet production line. For example, the SFSP hammer mill is used for wood and fruit shells, and the straw/alfalfa/husk/grass crusher is used for grass and straw. Different raw materials are equipped with different types of crusher.

Conveying Section : Conveying equipment is mechanical equipment that transports bulk cargo and unit goods from a loading point to an unloading point along a certain route in a continuous manner. The conveying equipment of RICHI machinery includes screw conveyor, scraper conveyor, belt conveyor and Bucket elevator.

Drying Section : To dry materials and remove the moisture from 50% to 15-17%. Itincludes: –Burningstove,tosupplyhotair –Drumdryer –Dischargingcyclone.

Pellet Mill: Wood pellet machine, also known as biomass pellet machine, has a wide range of raw materials: straw shells include wood, straw, sawdust, cotton stalks, rice husks, peanut shells, sunflower shells, coconut shells, coffee shells, bamboo, etc. . The grasses are alfalfa, hops, hemp, hay, grass, etc. In addition, there are organic fertilizer granulator, cat litter granulator and so on.

Cooling & Section : Pellets come out from pellet machine, its temperature is around 70℃, by cooling system, It can cool down to room temperature immediately. By momentary cooling, the hardness of pellets will become more stronger.

Screening Section : The forming rate of pellet machine is around 98 % , so there are still have 2% powder in pellets,by screening, sort out all the powders from pellets.

Packaging Section : There are three kinds of automatic packaging machines produced by RICHI machinery: powder packaging machines, granule packaging machines and (universal) dual-purpose packaging machines.

Dust Control System : A dust collection system is an air quality improvement system used in industrial production to improve breathable air quality and safety by removing particulate matter from the air and environment. Dust collection systems work on the basic formula of capture, convey and collect.

Production Line Description

The sunflower seeds hull pellet mill production line, also called the melon seeds shell pellet mill production line, can press the crushed and ground biomass wastes including sunflower seeds shell, peanut shell, straw, grass, sawdust, rice husk and tree bark into high density solid granular fuel products which belong to high efficient, green and regenerated energy. These biomass fuel products realize both the energy saving and emission reduction goal and good economic and social benefits.

Sunflower Seed Shell

Sunflower husks are the by-product of the dehulling of sunflower seeds. A well-managed dehulling process yields kernels with 18-22% hulls remaining. 100kg of seeds having 25% of hulls yield 16.5kg of hulls.

How To Collect Sunflower Seed Shells

1.Oil processing factory: While seeds are adopting in sunflower oil processing factory, shells used to be piled up or sent to a certain gathering place.

2.Snack processing plant: Both salty and sweet sunflower seed packed in bags can be seen in shops or supermarkets, so the pre-peeled shells can also be got there.

3.Chinese medicine making works: More than just a delicious snack, sunflower seed is also frequently used to make Chinese medicine together with folium mori and oriental sesame seed.

4.Food supply chain: Apart from oil, snack and medicine, we can also see sunflower seed on cakes, desserts and cookies. An intermediate food chain can always meet such requirements and in turn meet yours for sunflower seed shells.

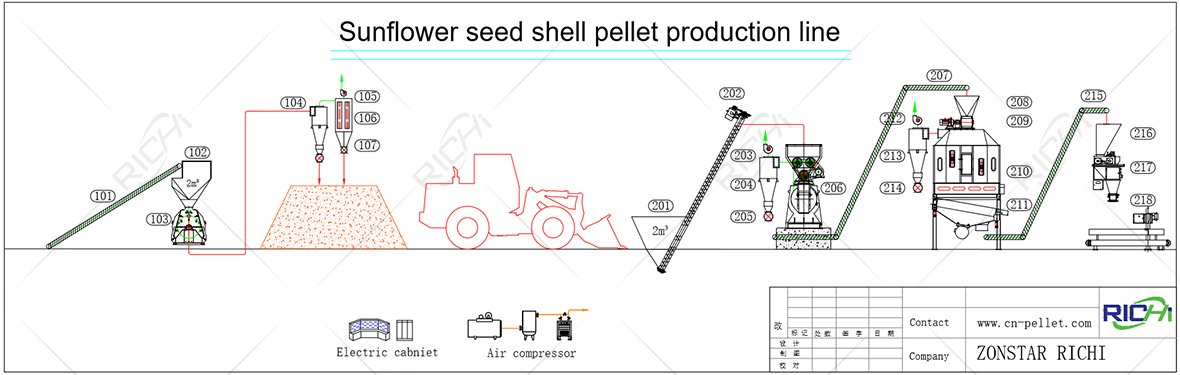

sunflower seeds pellet mill production line process

1. Crushing process

This process is to crush the sunflower seeds hull into fibrous pieces in order to be better pelletized.

2. Pelletizing process

This process is to grind the fibrous piece to pellet with 6mm,8mm,10mm and 12mm size, which is the core part of the whole production line. Before pelletizing, it needs to pick out iron, stone etc. our company adopts the most advanced ring die sunflower seeds shell pellet machine to pelletize, which features minimum energy consumption, minimum wearing, maximum stress and wide application. What's more, it has lowest sensitivity to different materials.

sunflower seed shell pellet production line flowchart

3. Cooling process

The discharged pellets have the temperature of 70-90 degree, which is unable to be packed. The cooling machine will make the temperature reduce to minis or plus 5 degree with room temperature. And then the cooled pellets are packed. This process uses counterflow cooling machine, which features good dust cleaning and short cooling time.

4. Screening process

During pelletizing, cooling and conveying process there will produce some powder for collision. So it needs to use vibrant screening machine to separate the unqualified pellets to achieve the requirement of the packing.

5. Packing process

The final pellets need to be packed, and then sold to customers. It usually uses bags and tons bags. This process packs according to customer's requirement. The packing machine is automatic, which features large capacity, less labor and less packing cost.

Sunflower seed shell is pressed into pellets by a pellet machine

Advantages of sunflower seed shell pellet mill

1. Excellent pressing effect, energy saving and efficient.

2. Reasonable structure, unique designation.

3. Even set compression roller, stable operation.

4. Anti-fatigue parts, high wear resisting performance.

5. Multiple functions, high efficiency.

6. Huge profit space, high economic benefit.